Iron Mining Process Plant

Iron Ore Processing: From Extraction to

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in 2022年1月1日 In many instances, China’s iron ore beneficiation plants are designed to recover more than just the iron minerals from the ore For example, the processing plants for the V–Ti Introduction: Overview of the global iron ore industry2023年6月2日 Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are Iron Ore production in the Pilbara Rio TintoLearn about the steps involved in iron ore processing, from crushing and grinding to separation Contact Multotec experts for guidance on iron processingThe six main steps of iron ore processing

.jpg)

Iron Ore Western Australia Rio Tinto

Significant innovations include a digital replica of the processing plant that’s accessible in real time by workers in the field; integrated mine automation and simulation systems Innovations at GudaiDarri include autonomous water 2019年2月28日 There are mainly three stages in the iron ore concentrate supply chain, ie, the mining stage, the ore concentrate production stage, and the distribution stage In the mining Integrated Production and Distribution Planning for the Iron 2023年12月19日 Discover the iron ore mining process, from blasting to export, and its vital role in steel production Learn about iron ore extraction and its historyIron Ore Mining Process: From Extraction to Export2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and Iron Ore Processing, General SpringerLink

.jpg)

Mineral Processing Plant SpringerLink

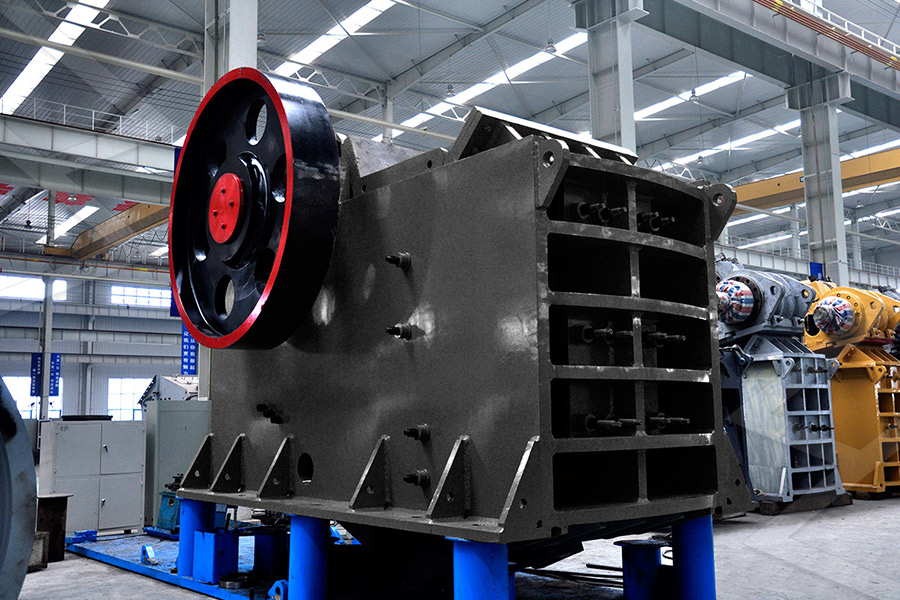

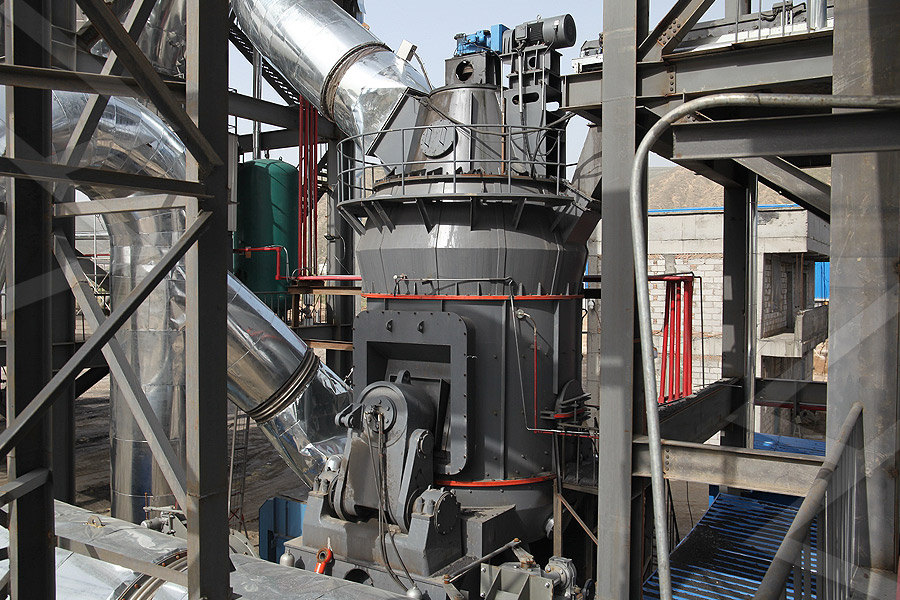

2023年5月3日 Mineral processing plant is a plant in which mineral processing is implemented to obtain concentrate products that are suitable for metallurgy or other industrial applications It is The Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces Transportation The taconite pieces are scooped up by electric Mining Process Iron Mining Association taconiteWith its completion, Northshore Mining is the first USbased iron ore processing facility to produce low silica DRgrade pellets The Northshore operation is producing DRgrade pellet feedstock inventory for ClevelandCliffs' Direct Iron Ore Facilities :: ClevelandCliffs Inc (CLF)2024年5月9日 The ore needs to be brought to the plant in an efficient way to enable the iron ore mining process to be carried out effectively Step 4: Crushing and Grinding – Ore Preparation for Separation At the plant, machines called Iron Ore Mining Essentials: Key to Steel

.jpg)

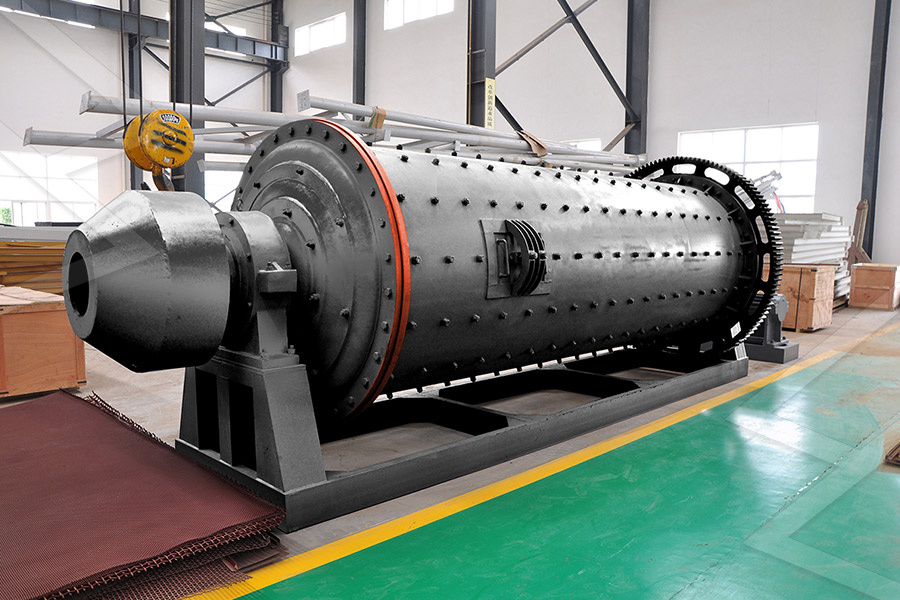

Comminution and classification technologies of iron ore

2022年1月1日 Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment Flow sheets for the Brockman 2 (87 MTpa) and Mount Tom Price (28 MTpa) processing plants are given in Figs 84 and 85 (Kinnel, 2013) The flow sheets are relatively simpleThe mining and production of iron ore can create fugitive dust emissions at a processing plant during land clearing and ground excavation and from onsite equipment traffic In addition, potential sources of fugitive dust during bulk material handling can include loading and unloading, ore crushing, stockpile erosion, and dust from conveyor systemsIron Ore: From Mining to Processing to Dust Control4 天之前 Iron Mining It is estimated that worldwide there are 800 billion tons of iron ore resources, containing more than 230 billion tons of iron 150TPH Iron Ore Processing Plant in Malaysia Material: hard rock type iron ore Capacity: 150TPH Country: Malaysia Feeding size: 0400mm Raw mineral description: 1 Weak magnetic iron 2 Contains slimeIron Mining Process Equipment Flow Cases JXSC2023年10月2日 In the dynamic world of mining, Derrick Corporation has become synonymous with innovation W ith a legacy rooted in Australian iron ore processing since the 1950s, Derrick Corporation continues to Revolutionising iron ore processing Australian Mining

.jpg)

The process Kaunis Iron

Kaunis Iron’s openpit mine in Pajala is just the starting point of the ore’s journey to customers around the world Here you can read about the process to refine the muchwanted iron ore In the screening plant, the larger pieces are separated from the finer fragments before being transported to the stockpile where they are stored 2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter Iron Ore Pelletizing Process: An Overview IntechOpenSome of the potential environmental effects of metal mines are summarized on Table 82 All mining activities result in a loss of natural environment because land has to be cleared and is no longer available for or useful to the plants and animals that once lived there Mining involves blasting, breaking and crushing rock, and so dust is created82: Mining and Ore Processing Geosciences LibreTexts2024年8月15日 Learn about mineral processing plants and relevant equipment to optimize your processing flow and equipment choices platinum group metals, as well as iron and manganese Froth flotation: This technique Mineral Processing Plants: What You Need to

.jpg)

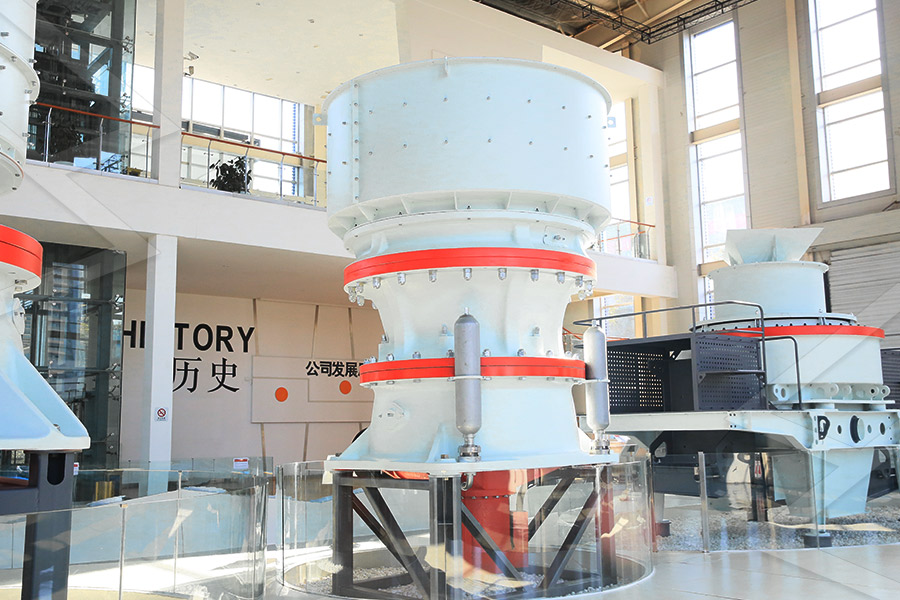

Iron Ore Beneficiation Plant Equipment For

2023年9月4日 Jig machine: processing 30 (2)~05mm coarse iron ore; Shaking table: separating 2~0037mm fine iron ore particles; Spiral chute: processing 01037mm iron ore with low mud content 4 Iron ore dewatering equipment The In 2017 the Karara Iron Ore Project achieved an annual iron ore concentrate production rate of 8 million tonnes per annum (Mtpa) Karara is now examining opportunities to increase its production rate beyond 8Mtpa consistently, as part of a broader strategy to improve the longterm economic viability of its magnetite mining operationProcessing – Karara Mining Limited2023年1月1日 Dry processing of iron ore: In dry processing of iron ore, ROM is generally crushed below 40 mm through threestage crushing and thus segregated by screening into 10–40 and −10 mm fractions For softer ore, tumbler index is generally low and hence lump ore is crushed below 10 mm to produce 100% fine product Yield from the plants has been Iron ore beneficiation: an overview ScienceDirect2024年6月25日 Sino Iron is the largest magnetite mining and processing operation in Australia – 100km south west of Karratha in Western Australia’s resourcerich Pilbara region We use traditional open pit mining techniques to excavate the ore, then put it through a rigorous beneficiation process right here on site, producing a high grade, premium Our Operation Citic Pacific Mining

Iron Ore Supply Chain: From Mining to Steel Production

2023年10月25日 Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is then transported to processing plants for beneficiation and further refinement The refined iron ore is then transported to steel mills for Complete plant process audits, Increase separation efficiency with separators used across the world in extraction of gold, iron ore, coal, platinum more View more This is the processing of ore after mining to provide a more concentrated material for extractive metallurgy What is also important about this processing is that it Mineral Processing Plants Multotec2021年5月13日 SNIM Open Pit Iron Ore Mining – Mauritania Miferma (Mines de Fer de Mauritanie) was created in 1952 to exploit iron ore deposits in the Kedia d'Idjil area of north Producer of SNIM inaugurated the new Guelbs processing plant in Zouerate, as part of the Guelb II project The new mining complex adds 4Mtpa of concentrates and represents a SNIM Open Pit Iron Ore Mining Mauritania Mining 2023年11月20日 Iron, one of the most essential metals in modern society, plays a vital role in various industries, including construction, automotive, and manufacturing With the increasing demand for iron products, the establishment of an iron processing plant presents a lucrative opportunity for entrepreneurs and investorsHow Much Is An Iron Ore Processing Plant Miningpedia

.jpg)

7 Environmental Impacts of Iron Ore Mining

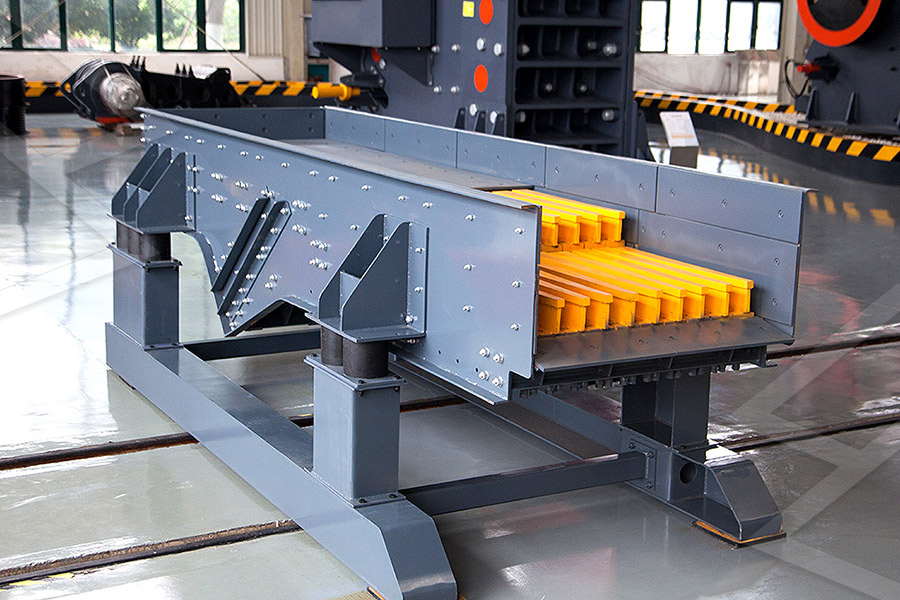

Steel production uses over 98% of the iron ore available on the global market Iron ore is a significant material that is used to extract metallic iron Due to the increasing demand for metals, mining, and processing must be done Significant innovations include a digital replica of the processing plant that’s accessible in real time by workers in the field; integrated mine automation and simulation systems Innovations at GudaiDarri include autonomous water Iron Ore Western Australia Rio Tinto2024年8月14日 43 Integration with Existing Mining Operations Plant based iron extraction techniques can be integrated with existing mining operations For example, in areas where there are already iron mines, plants can be planted in the surrounding areas or on reclaimed mine land to extract any remaining iron from the soil Harvesting and processing Sustainable Mining: The Role of Plants in Iron ExtractionProcessing plants such as those of Roy Hill are characterized by a high number of screening devices In fact, 16 banana screens are used in that plant alone Fig 9 shows a 40 Mta iron ore processing plant operated by Vale in the Carajas Mine The photo shows parallel linear vibrating screens for secondary screeningAdvances in screening technology in the mining sector

Simec Mining 950tph Iron Ore Beneficiation Wash Plant CDE

The two wet processing plants at Iron Knob and Iron Baron, with a combined throughput of 950 tonnes per hour, were designed, manufactured and delivered within 18 months from signing which was unprecedented for an Australian mining project of this nature2023年3月1日 Downstream mineral processing in Southeast Asia's mining industry, which lags other regions, can enhance productivity with digital and analytics Asia can go further by pursuing digital and analytics (DnA) opportunities By implementing DnAenabled practices, processing plants can capture the value of data across the value chain, optimize Optimizing processes in Southeast Asia’s mining industry02 China 3500TPD Iron Mining and Processing Plant Ore Properties The metallic minerals were magnetite, hematite, limonite; the nonmetallic mineral was quartz Only Fe in the raw ores has recycling value, and the raw ores belong to original Iron Processing Solution Miningpedia2018年9月18日 Characterization and beneficiation of dry iron ore processing plant reject fines of Khondbond region, India, was investigated Different characterization techniques viz size analysis, sizewise chemical and density analysis, Xray diffraction analysis, sinkfloat analysis, thermo gravimetric analysis, scanning electron microscopy, and QEMSCAN were carried out Characterization and Beneficiation of Dry Iron Ore Processing Plant

Compagnie minière IOC ironoreca

Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in SeptIles","3821":"The Iron Ore Company of Canada is owned The Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces Transportation The taconite pieces are scooped up by electric Mining Process Iron Mining Association taconiteWith its completion, Northshore Mining is the first USbased iron ore processing facility to produce low silica DRgrade pellets The Northshore operation is producing DRgrade pellet feedstock inventory for ClevelandCliffs' Direct Iron Ore Facilities :: ClevelandCliffs Inc (CLF)2024年5月9日 The ore needs to be brought to the plant in an efficient way to enable the iron ore mining process to be carried out effectively Step 4: Crushing and Grinding – Ore Preparation for Separation At the plant, machines called Iron Ore Mining Essentials: Key to Steel

.jpg)

Comminution and classification technologies of iron ore

2022年1月1日 Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment Flow sheets for the Brockman 2 (87 MTpa) and Mount Tom Price (28 MTpa) processing plants are given in Figs 84 and 85 (Kinnel, 2013) The flow sheets are relatively simpleThe mining and production of iron ore can create fugitive dust emissions at a processing plant during land clearing and ground excavation and from onsite equipment traffic In addition, potential sources of fugitive dust during bulk material handling can include loading and unloading, ore crushing, stockpile erosion, and dust from conveyor systemsIron Ore: From Mining to Processing to Dust Control4 天之前 Iron Mining It is estimated that worldwide there are 800 billion tons of iron ore resources, containing more than 230 billion tons of iron 150TPH Iron Ore Processing Plant in Malaysia Material: hard rock type iron ore Capacity: 150TPH Country: Malaysia Feeding size: 0400mm Raw mineral description: 1 Weak magnetic iron 2 Contains slimeIron Mining Process Equipment Flow Cases JXSC2023年10月2日 In the dynamic world of mining, Derrick Corporation has become synonymous with innovation W ith a legacy rooted in Australian iron ore processing since the 1950s, Derrick Corporation continues to Revolutionising iron ore processing Australian Mining

The process Kaunis Iron

Kaunis Iron’s openpit mine in Pajala is just the starting point of the ore’s journey to customers around the world Here you can read about the process to refine the muchwanted iron ore In the screening plant, the larger pieces are separated from the finer fragments before being transported to the stockpile where they are stored 2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter Iron Ore Pelletizing Process: An Overview IntechOpenSome of the potential environmental effects of metal mines are summarized on Table 82 All mining activities result in a loss of natural environment because land has to be cleared and is no longer available for or useful to the plants and animals that once lived there Mining involves blasting, breaking and crushing rock, and so dust is created82: Mining and Ore Processing Geosciences LibreTexts