Ball Mill For Grinding Silica Sand With Capacity Of 0.56130tph

Silica Sand Grinding Ball Mill With Capacity Of 056130tph

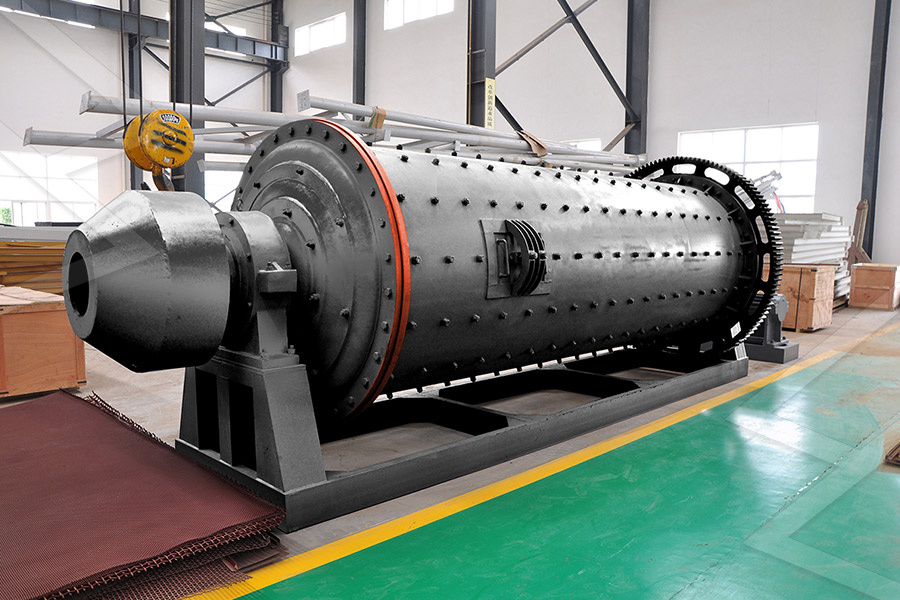

Silica Sand Grinding Ball Mill With Capacity Of 056130tph Buy Cement Mill silica Sand Ball Mill used Ball Mill Sale Product on Alibaba056130tph Grinding Silica Sand Ball Mill Machine, You can get more details 056130tph Grinding Silic056130tph Grinding Silica Sand Ball Mill Machine, You can get more details about 056130tph Grinding Silica Sand Ball Mill Machine from mobile site on Alibaba Production 056130tph Grinding Silica Sand Ball Mill MachineSilica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machine Silica sand is a chemically stable silicate mineral with particle size Wet Dry Silica Sand Ball Mill for Silica Sand

.jpg)

Silica Sand Grinding Ball Mill Ball Mill and Gold Ball Mill

2024年10月25日 Silica Sand Grinding Ball Mill, Find Details and Price about Ball Mill Gold Ball Mill from Silica Sand Grinding Ball Mill Henan Yuhui Mining Machinery Co, Ltd2024年11月12日 Raw material mill is used widely for grinding (both drying and grinding) cement raw material and other materials in building material, metallurgical, electric and chemical Raw Material Ball Mill for Grinding Silica Sand2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball Comparative Study on Improving the Ball Mill Process 4 天之前 There are two ways of grinding: the dry process and the wet process The ball mill is a horizontal rotating device transmitted by the outer gear The materials are transferred to the grinding chamber through the quill shaft Capacity 20tph Ceramic Ball Mill / Silica Sand

.jpg)

PAPER OPEN ACCESS Parameter Optimization of Ball

2019年12月13日 The experiment confirmation value particle size of silica sand can be accepted because the value is in the range of confidence intervals, figure 6 Figure parison of 2020年10月1日 In this paper, we report on a detailed experimental analysis of the longterm grinding behavior of silica sand as a model material in an oscillatory ball mill for a broad range Evolution of grinding energy and particle size during dry ball 056130tph Grinding Silica Sand Ball Mill Machine No reviews yet Henan Winnermac Heavy Industrial Machinery Co, Ltd 5 yrs CN Hover to zoom in Key attributes Production 056130tph Grinding Silica Sand Ball Mill Machine2023年10月9日 A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering lead ore, zinc ore, kaolin, bentonite, feldspar, Ball Mill Ball Grinding Mill SKE

.jpg)

Small Ball Mill Capacity Sizing Table 911Metallurgist

2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for Calculate Ball Mill Grinding Capacity David ; February 14, 2016; 6:03 pm; Prev Previous Hydrometallurgy Articlesin a tumbling ball mill and about 50 times greater than that in a stirred ball mill2) Another result is given in Fig 3, from which it is seen that even small glass beads with a low density can be used to grind hard materials such as silica sand in the planetary ball The Mechanism and Grinding Limit of Planetary Ball 2024年11月28日 It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plant Ball Mills Types Ball Mill JXSC Mineral2024年10月12日 Silica sand Silica sand, also known as silica or quartz sand Silica sand is refractory particles with quartz as the main mineral component and particle size of 0020mm3350mm It is divided into artificial silica sand and washed sand and scrub sand according to different mining and processing methods Natural silica sand such as selected silica sand grinding mill, silica sand ball mill, silica sand

.jpg)

Silica Sand Processing Plant JXSCTeam

The silica sand from the attrition scrubber enters the trommel screen to wash and screen out 006mm and over 06 mm silica sand The 006mm silica sand enters two spiral washing machines and gets overflow and underflow materialSand ball mill is the ball mill that can make sand, so it is also called ball mill sand making machine or sand mill The sand ball mill is mainly used for finely crushed sand making operations of river pebble, granite, basalt and other materials with higher hardness Since the machinemade sand processing by the sand ball mill is comparable to Sand Ball Mill River Pebble, Gravel Sand Processing for 2020年10月1日 The energy efficiency of dry fine grinding process of powders dramatically declines with decreasing particle size, and represents a growing concern in various cuttingedge technical applications for pharmaceutical and cosmetic products, advancedceramics, and food industryIn this paper, we report on a detailed experimental analysis of the longterm grinding Evolution of grinding energy and particle size during dry ball 2024年8月6日 The company′s main products are: Wet ball mill (grinding) production line, dry ball mill with sorting machine production line, high purity stone English system sand machine, air classifier, the board type magnetic separator, quartz pickling equipment, drum washing machine, vertical ring high gradient magnetic separation machine, hydraulic Silica Sand Processing Equipment Micron Grinding Ball Mill

Calculate and Select Ball Mill Ball Size for

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA 2024年11月15日 Introduction of Energysaving grid Ball Mill Energysaving grid (overflow) ball mill is the key equipment after the material is broken and crushedThey are used for dry or wet grinding of various ores and other materialsIt is widely used in mineral processing,cement and silicate products,new building materials,refractory materials,chemical fertilizers and glass Mining Ball Mill Grinding Machine, High Capacity Iron Ore 2020年8月1日 A series of wet grinding experiments using calcite, pyrophyllite, and talc powder by a vertical type planetary ball mill, in which the size and distribution of grinding balls were varied with the Evolution of grinding energy and particle size during dry ball 2024年6月18日 with previous experimental measurements in a ball mill 2 Materials and Methods 21 Raw material In this work, we used a commercial silica sand composed of 9860% of pure silica for filtration applications, marketed by Euromortier It is a sieved sand between 05 mm and 14 mm All the samples used in this study come from the same batchEvolution of grinding energy and particle size during dry

.jpg)

High Energy Industrial Silica Sand Limestone Stone Ball Mill Grinding

2024年11月8日 High Energy Industrial Silica Sand Limestone Stone Ball Mill Grinding Machine, Find Details and Price about Hard Stone Ball Mill Silica Sand Ball Mill from High Energy Industrial Silica Sand Limestone Stone Ball Mill Grinding Machine Gongyi Hengchang Metallurgical Building Material Equipments Plant [ Capacity ]: 06290 t/h2024年11月14日 Continuous Ball Mill With Rubber Liner for Grinding Silica Sand: Continuous Ball Mill With Rubber Liner For Grinding Silica Sandis primarily a cylindrical device used for grinding or mixing different material such as chemicals, raw material, ores and other related mining materialsIt rotates around a horizontal axis that is partly filled with the material to be Continuous Ball Mill with Rubber Liner for Grinding Silica Sand2024年4月2日 Silica nanoparticles were prepared by ball milling method The planetary ball mill grinding jars and grinding balls used are from stainless steel with diameter of 10 mm with maximum Rotational Synthesis of Silica Nanoparticles from Malpe Beach Sand 2023年8月10日 Features of silica sand rod mill: Feed particle size: ≤50 mm Discharge particle size: 08330147 mm Used for grinding silica sand to achieve the required particle size, with a processing capacity of 062180 t/h The particle size of the ground silica sand product is relatively uniform, and the phenomenon of overgrinding is lessSilica Processing Plant 4 Major Stages to Make Silica Sand

PAPER OPEN ACCESS Parameter Optimization of Ball

2019年12月13日 The experiment confirmation value particle size of silica sand can be accepted because the value is in the range of confidence intervals, figure 6 Figure parison of mean calculation (a) results of confirmation (b) optimization results2020年5月1日 The ball mill capacity Q is obtained from the ratio of the power of the pinion required by the ball mill 3356: Hydrocyclone feeding7: 6249: 3179: Hydrocyclone overflow1 The average grinding rate of the +60 mm sized particles increased with an increase in the size of the ball medium from 0 of Φ80 mm to 0 of Φ100 mm Enhancing the capacity of largescale ball mill through 2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution 14:00:56 The size and composition of the grinding balls, rotational speed of the mill, and duration of the grinding process all play vital roles The selection of grinding balls for silica sand refinement is a critical decision that directly impacts process efficiency and product quality With various types of grinding balls Silica Sand Refinement: Leveraging Grinding Balls for

Factors Affect The Output and Quality of Ball

2023年12月28日 The safety factor is low, the service life is short, etc, and these will inevitably affect the continuous production of the ball mill Therefore, the overall performance of the ball mill is better 3 The ball mill is of good quality China Ball Mill catalog of Mining Machine Dry Grinding Mill Ceramic Ball Mill for Grinding Silica Sand 4 Tph, Small Scale Gold Mining Equipment Ball Mill Grinding Rock Grinder Mill provided by China manufacturer Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd, page1 Gold Mining Equipment 500kg Capacity Gold Ore 700*900 Ball Mill Jiangxi Hengchang Mining Machinery 2020年1月13日 The Vertical vibrating mill is a new design of vibrating mills which are used to produce micropowders, and nanopowders This paper studies the effect of four different parameters (rotational EXPERIMENTAL STUDY OF THE EFFECT OF BALL DIAMETER, 2024年11月11日 The capacity of such mills is determined by the drum size and low process dynamics, which makes them unsuitable for superfine grinding The planetary mill is a ball mill type; however, due to the complex and highintensity movement of grinding bodies, it provides particle size reduction in a much shorter time Figure 5 shows the dispersity Grinding of Biogenic Silica Glass and Ceramics Springer

.jpg)

Ball Mill an overview ScienceDirect Topics

A ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition (22), who varied the proportion of the mill filled with balls from 02 to 08 of the volume of the mill The grinding rates were found to be a maximum at loadings between 03 and 04 An increase in the 2019年8月14日 The impact breaking force, the grinding capacity and the ball mill capacity are relative with the size of steel balls The experiment results show that, at the same amount, the size of steel balls is in direct proportion to the impact breaking force, the grinding capacity and the ball mill capacityThe Ultimate Guide to Ball Mills MiningpediaRSG Inc supplies a wide range of ball mills, from 3 kw pilot plant test mills to 4000 kw high capacity cement, ash and slag mills RSG Inc has a fully equipped ball mill test plant for sample evaluation to ensure accurate scale up and optimum plant performance 45 kw dry ball mill for silica sand grinding 1500 kw dry ball mill for iron ore Ball mills dry grinding systems fine powder processing2015年6月2日 Silica nanoparticles have been prepared by planetar y ball mill method at room temperature at different milling hours using Malpe beach sand, Karnataka, India(PDF) Synthesis of silica nanoparticles from malpe beach sand

Ball Mill Ball Grinding Mill SKE

2023年10月9日 A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering lead ore, zinc ore, kaolin, bentonite, feldspar, 2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for Calculate Ball Mill Grinding Capacity David ; February 14, 2016; 6:03 pm; Prev Previous Hydrometallurgy ArticlesSmall Ball Mill Capacity Sizing Table 911Metallurgistin a tumbling ball mill and about 50 times greater than that in a stirred ball mill2) Another result is given in Fig 3, from which it is seen that even small glass beads with a low density can be used to grind hard materials such as silica sand in the planetary ball The Mechanism and Grinding Limit of Planetary Ball 2024年11月28日 It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining, grinding, screening, crushing plant Ball Mills Types Ball Mill JXSC Mineral

silica sand grinding mill, silica sand ball mill, silica sand

2024年10月12日 Silica sand Silica sand, also known as silica or quartz sand Silica sand is refractory particles with quartz as the main mineral component and particle size of 0020mm3350mm It is divided into artificial silica sand and washed sand and scrub sand according to different mining and processing methods Natural silica sand such as selected The silica sand from the attrition scrubber enters the trommel screen to wash and screen out 006mm and over 06 mm silica sand The 006mm silica sand enters two spiral washing machines and gets overflow and underflow materialSilica Sand Processing Plant JXSCTeamSand ball mill is the ball mill that can make sand, so it is also called ball mill sand making machine or sand mill The sand ball mill is mainly used for finely crushed sand making operations of river pebble, granite, basalt and other materials with higher hardness Since the machinemade sand processing by the sand ball mill is comparable to Sand Ball Mill River Pebble, Gravel Sand Processing for 2020年10月1日 The energy efficiency of dry fine grinding process of powders dramatically declines with decreasing particle size, and represents a growing concern in various cuttingedge technical applications for pharmaceutical and cosmetic products, advancedceramics, and food industryIn this paper, we report on a detailed experimental analysis of the longterm grinding Evolution of grinding energy and particle size during dry ball

Silica Sand Processing Equipment Micron Grinding Ball Mill

2024年8月6日 The company′s main products are: Wet ball mill (grinding) production line, dry ball mill with sorting machine production line, high purity stone English system sand machine, air classifier, the board type magnetic separator, quartz pickling equipment, drum washing machine, vertical ring high gradient magnetic separation machine, hydraulic