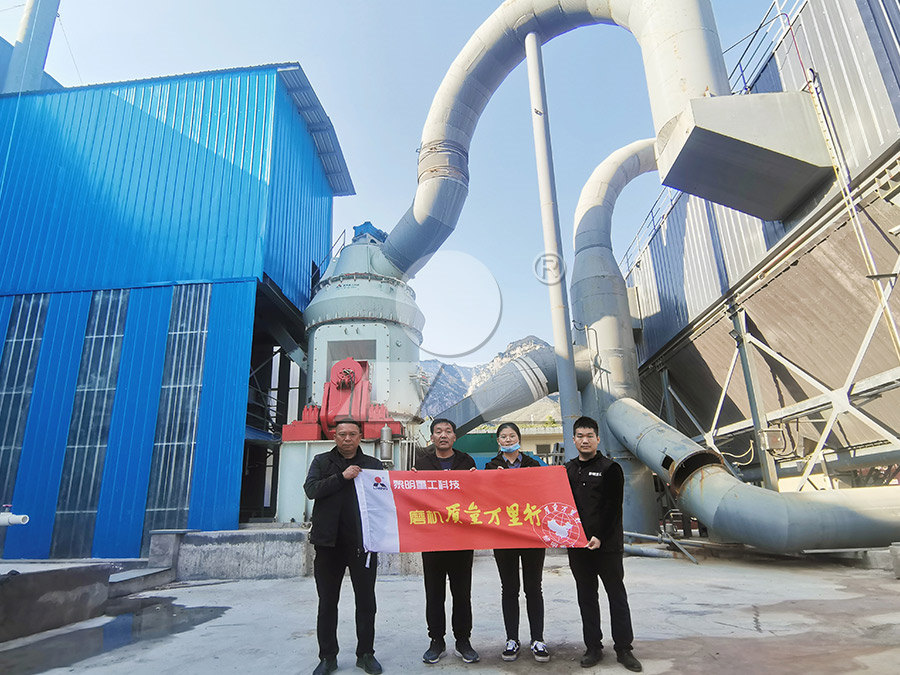

Agitating Ball Mill Application In Turkmenistan

PULVIS Hosokawa Alpine

Gain competitive advantages in dry grinding with our process engineering solution The milling part is located at the bottom of the machine Feed material is ground by agitated media that The fluidised bed opposed jet mill is the second most common type of jet mill In Jet MillsThe agitated media mill is a special form of ball mill, in which an agitator with stirring elements or an agitator body sets the balls in motion Hosokawa Alpine offers a range of agitator bead mills for wet or dry grindingBall Mills Agitated Media Mills Hosokawa 2020年6月9日 The PULVIS, a combination of a vertical agitated ball mill and a high performance air classifier represents a further milestone on our way The milling part is located at the ALPINE PULVIS Hosokawa Alpine

.jpg)

Recent Advances in BallMilled Materials and

2024年6月7日 Ball milling has the capacity to change materials’ crystal structure, specific surface areas, pore volumes, and particle sizes and even promote grafting reactions to obtain functional groups to surfaces This 2020年12月29日 In this talk, we will discuss the principle of the Attritor along with its applications The Attritor is a grinding mill containing internally agitated media It has been ATTRITOR GRINDING AND DISPERSING EQUIPMENT by 2001年3月26日 The attritor, or stirred ball mill, is a grinding mill containing internally agitated media There are quite a few types of attritors; they can be categorized as dry grind, wet grind, regular speed (to 400 rpm) and high New Developments in Attritors PCI Magazine2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide BALL MILLS Ball mill optimisation Holzinger Consulting

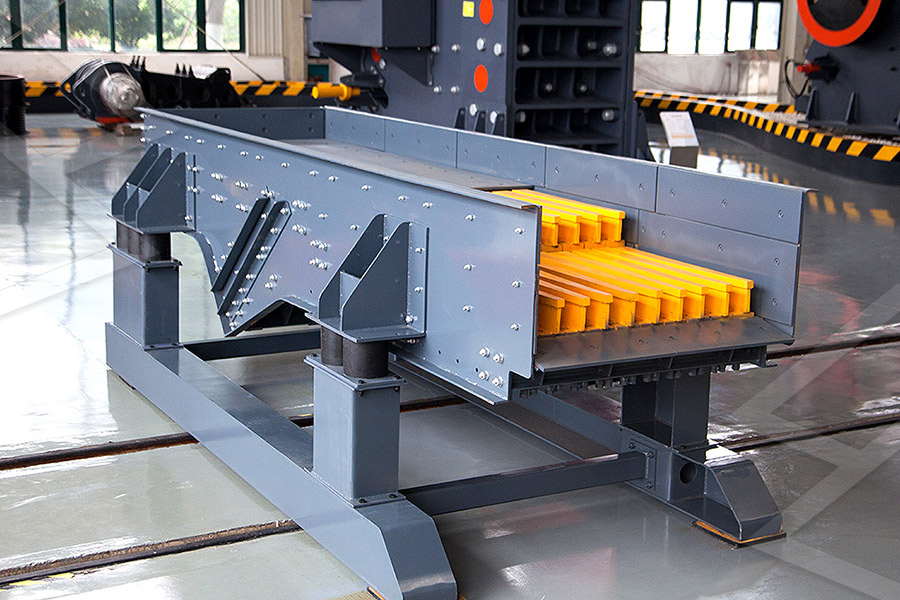

The Effect of the Bending Angle of the Blades of the

2022年9月2日 The shape of the blades of the horizontal agitating ball mill will greatly affect the efficiency of the ball mill In this article, by bending the end of the mixing blade, using discrete element 2024年2月20日 This article from Retsch discusses how ball mills play an essential role in the value chain in battery production the four main application areas of Retsch laboratory ball mills in battery technology will be outlined How Ball Mills Contribute to Battery Technology2019年8月1日 Energy related research work was carried out by Iwasaki et al (2006), they studied the effect of three types of media mills, a horizontal tumbling ball mill, vertical agitating ball mill and bead mill on the deformation of spherical copper powder The particle size distributions were measured before and after grinding and the deformation of A review on mechanical activation and mechanical alloying Abstract:This paper introduces the basic structure and working principle of GJM type agitating mill, analyzes the main design factors, such as agitating device, tank structure and wearresistant material; According to the characteristics of large flake graphite BGRIMM developed GJM type graphite special agitating mill, emphatically introduce the industrial application in domestic and GJM型石墨用搅拌磨机的研制与应用DEVELOPMENT AND

.jpg)

For grinding, agitating and dispersing samples

2024年9月12日 Cryogenic Mill IQ MILL2070 IQ2070100 or IQ2070200 Main unit, Sample container LSS set 1 ea, Grinding balls, SS Grinding Rod 12 1 ea, Insulation container 1 ea, etc Cryogenic Mill IQ MILL2070 With sample container LSS starter kit IQ2070100SKS or IQ2070200SKS Main unit, Sample container LSS set 3 ea, Grinding balls,2022年7月21日 Abstract The shape of the blades of the horizontal agitating ball mill will greatly affect the efficiency of the ball mill In this article, by bending the end of the mixing blade, using discrete element method and EDEM simulation to study the effect of blade bending angle on the efficiency of ball milling In this article, the degrees of blade bending are 0 degrees, 3 degrees, The Effect of the Bending Angle of the Blades of the A wet agitating ball mill wherein a shaft (5) rotated by a motor is axially hollow at an upper portion thereof to form a discharge port (9) communicating with a slurry discharge port, and has at a lower portion thereof rotors (11) A separator (4) comprises a pair of disks (21) and blades (22) connecting both disks to form an impeller which rotates to impart centrifugal forces to slurry Wet agitating ball mill and method Google PatentsThe Pulvis was developed as a dry type energyefficient ultrafine agitating media mill with integrated classifier To obtain particles of submicron size with impact type mills or jet mills very large milling energy is required On the other hand, media agitating mill such as ball mills is possible to grind down to submicron range with energy saving features, however, problem HOSOKAWAMICRON CORPORATION

Ball Mills in the Mineral Processing Industry MechProTech

2024年5月27日 Applications of Ball Mills in Mineral Processing Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc They fall part of the comminution process, where ores are crushed to separate valuable minerals from the gangue In mineral processing plants, ball mills are employed in which is induced by the kinetic energy of a ball mill In the HighEnergy Ball Mill Emax for example, an unrivalled acceleration of 76 g can be obtained, if running at its maximum speed of 2000 rpm SELECTING THE MOST SUITABLE BALL MILL To identify the most suitable ball mill for a particular application, the task and required out Unlocking the potential: The role of Ball Mills in battery An agitating mill, particularly an agitating ball mill, comprising a housing having an inlet for material to be ground and for air, an outlet for fines and air, and at least one horizontal agitator shaft which is provided with agitating members The outlet for fines and air has a large area and is provided in the top wall of the housing and extends throughout the length and width of the top USA Agitating mill, particularly agitating ball mill2018年11月1日 The key part is the agitating drum which is made of steel with a 300 mm inner diameter, 100 mm length and 10 mm thickness The rotational axis of the agitating vanes is the same as the agitating cylindrical drum Four groups of four blades are installed on the rotational axis with 90° apart in each groupGranular flow characteristics and heat generation mechanisms

MaxxMill® Agitate media mill Eirich

2023年9月12日 Agitate media mill for dry and wet grinding ironfree adjustable grain size distribution • Final product: up to d 97 =5 μm • Feed material: up to 2 mm • Hardness: up to 9 Mohs Range of application Continuous dry and wet grinding of coarsegrained materials to fineground and ultrafineground pro by ball retaining device Flexibility AGICO ball mills can handle more than 200 kinds of raw materials We offer various types of dry grinding ball mills and wet grinding ball mills with fair price and high grinding efficiency, such as cement ball mill, gold ball mill, etc +86 Home; Ball Mill Application Menu Toggle Cement Ball Mill; Gold Ball Mill; Coal Ball BALL MILL APPLICATION2023年3月27日 Ball Mills in research Labs: Importance and Applications Ball mills are a type of grinding machine used to grind and blend materials for use in various industries, including the chemical, pharmaceutical, and mineral processing industriesThey operate by rotating a hollow cylinder around its horizontal or vertical axis, with the material to be ground added to the Ball Mills in research Labs: Importance and Applications2023年9月8日 This article will take an indepth look at the application of ball mills in the food industry, as well as its working principles and advantages Working Principle of Industrial Ball Mill A ball mill is a mechanical device that usually consists of a rotating cylinder with steel balls or other hard spheres of a certain size placed insideWhat Is An Industrial Ball Mill In The Food Industry

.jpg)

agitating ball mill application in Mexico natabistro

CNU The utility model provides a kind of agitating ball mill, is transformed by shaft, and the upper end of shaft is splined shaft, and the lower end of driving shaft is spline housing, and spline housing is supported between two bearings, and splined shaft is connected with spline housingWhen spline housing rotates, while shaft is rotated thereupon being paid ALPINE PULVIS DRY AGITATING MEDIA MILL 4 Pages Add to favorites a combination of a vertical agitated ball mill and a high performance air classifier represents a further milestone on our way temperature unsensitive materials In the grinding kW h/kg process also additives can be used Typical application for the PULVIS are for ALPINE PULVIS DRY AGITATING MEDIA MILL DirectIndustry2024年3月7日 The application of drygrinding ball mills in mineral processing provides significant advantages in terms of costeffectiveness, environmental sustainability, and process control These benefits make the ball milling process a preferred method for refining and processing raw materials in the mining industry, offering a more efficient and Application of Dry Ball Milling in Mineral Processing2012年6月1日 The applications of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement production, chemical industry, Ball mills can grind a wide range of materials (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Turkmenistanball Polandball Wiki

3 天之前 Turkmenıstanball, formerly known as Turkmenıaball and offıcıally known as the North Korea 20 Republıc of Turkmenıstanball, ıs a carpet republıc countryball ın Central Asıa that ıs a dıctatorshıp Its area ıs 469,930 square An agitator ball mill for finely grinding or dispersing material has a cylindrical or conical grinding chamber for accommodating grinding bodies and for accommodating the material which is to be ground or dispersed It also has an inlet, which is arranged at one end of the grinding chamber, an agitator, which extends in the axial direction into the grinding chamber and has agitating USA1 Agitator ball mill Google PatentsA rod mill uses long cylindrical rods as the grinding medium, while a ball mill uses steel balls The main difference between the two is the method of grinding: a rod mill can grind material by tumbling it with the rods, while a ball mill uses the balls to perform the grinding actionThe Versatile Applications of Rod Mill in Various Industries2015年11月30日 A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls occupying 3050% of the volume to facilitate grinding as the shell rotates Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials Read lessBall Mill PPT SlideShare

A Review of the Grinding Media in Ball Mills for Mineral

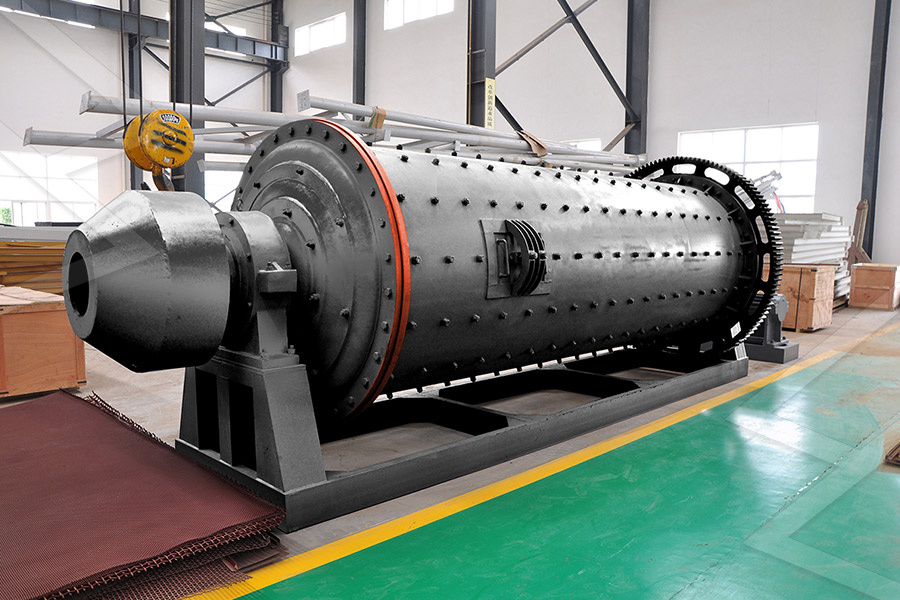

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral The applications of ball mills are diverse and encompass a wide range of industries and scientific research fields These versatile milling machines are used for various processes including grinding, mechanical alloying, and material property alteration Let's delve into the practical applications of ball mills in the context of mining ores Understanding the Advantages and Disadvantages of Ball Mills Application number US10/525,613 Other languages English (en) Other versions USA1 (en Inventor Armin Geiger Olaf Eichstaedt Agitating ball mills are used in the area of foodstuffs and in the manufacture of fine particles down to the nanometer range in size Particles or agglomerates suspended in a liquid are here conveyed into the USB2 Ball mill provided with an agitator Google 2023年11月14日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as influenced by three basic wear mechanisms: impact, abrasion, and A Review of the Grinding Media in Ball Mills for Mineral

Ball mills for various applications Gebr Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials Select application envisaged Feed material Quicklime and lime hydrate; Other materials; feed material dedusting feed material ground product grinding balls adjustable discharge slots F 2022年9月2日 The shape of the blades of the horizontal agitating ball mill will greatly affect the efficiency of the ball mill In this article, by bending the end of the mixing blade, using discrete element The Effect of the Bending Angle of the Blades of the 2024年2月20日 This article from Retsch discusses how ball mills play an essential role in the value chain in battery production the four main application areas of Retsch laboratory ball mills in battery technology will be outlined How Ball Mills Contribute to Battery Technology2019年8月1日 Energy related research work was carried out by Iwasaki et al (2006), they studied the effect of three types of media mills, a horizontal tumbling ball mill, vertical agitating ball mill and bead mill on the deformation of spherical copper powder The particle size distributions were measured before and after grinding and the deformation of A review on mechanical activation and mechanical alloying

GJM型石墨用搅拌磨机的研制与应用DEVELOPMENT AND

Abstract:This paper introduces the basic structure and working principle of GJM type agitating mill, analyzes the main design factors, such as agitating device, tank structure and wearresistant material; According to the characteristics of large flake graphite BGRIMM developed GJM type graphite special agitating mill, emphatically introduce the industrial application in domestic and 2024年9月12日 Cryogenic Mill IQ MILL2070 IQ2070100 or IQ2070200 Main unit, Sample container LSS set 1 ea, Grinding balls, SS Grinding Rod 12 1 ea, Insulation container 1 ea, etc Cryogenic Mill IQ MILL2070 With sample container LSS starter kit IQ2070100SKS or IQ2070200SKS Main unit, Sample container LSS set 3 ea, Grinding balls,For grinding, agitating and dispersing samples 2022年7月21日 Abstract The shape of the blades of the horizontal agitating ball mill will greatly affect the efficiency of the ball mill In this article, by bending the end of the mixing blade, using discrete element method and EDEM simulation to study the effect of blade bending angle on the efficiency of ball milling In this article, the degrees of blade bending are 0 degrees, 3 degrees, The Effect of the Bending Angle of the Blades of the A wet agitating ball mill wherein a shaft (5) rotated by a motor is axially hollow at an upper portion thereof to form a discharge port (9) communicating with a slurry discharge port, and has at a lower portion thereof rotors (11) A separator (4) comprises a pair of disks (21) and blades (22) connecting both disks to form an impeller which rotates to impart centrifugal forces to slurry Wet agitating ball mill and method Google Patents

.jpg)

HOSOKAWAMICRON CORPORATION

The Pulvis was developed as a dry type energyefficient ultrafine agitating media mill with integrated classifier To obtain particles of submicron size with impact type mills or jet mills very large milling energy is required On the other hand, media agitating mill such as ball mills is possible to grind down to submicron range with energy saving features, however, problem 2024年5月27日 Applications of Ball Mills in Mineral Processing Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc They fall part of the comminution process, where ores are crushed to separate valuable minerals from the gangue In mineral processing plants, ball mills are employed in Ball Mills in the Mineral Processing Industry MechProTechwhich is induced by the kinetic energy of a ball mill In the HighEnergy Ball Mill Emax for example, an unrivalled acceleration of 76 g can be obtained, if running at its maximum speed of 2000 rpm SELECTING THE MOST SUITABLE BALL MILL To identify the most suitable ball mill for a particular application, the task and required out Unlocking the potential: The role of Ball Mills in battery