Ball Mills With Ceramic Lining

.jpg)

CERAMIC BALL MILL LINING BRICKS AND GRINDING MEDIA

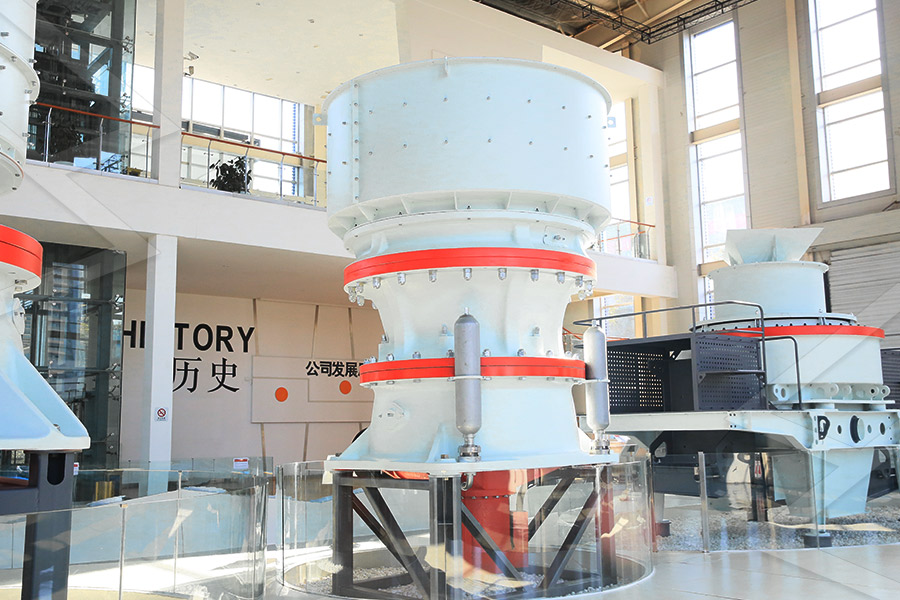

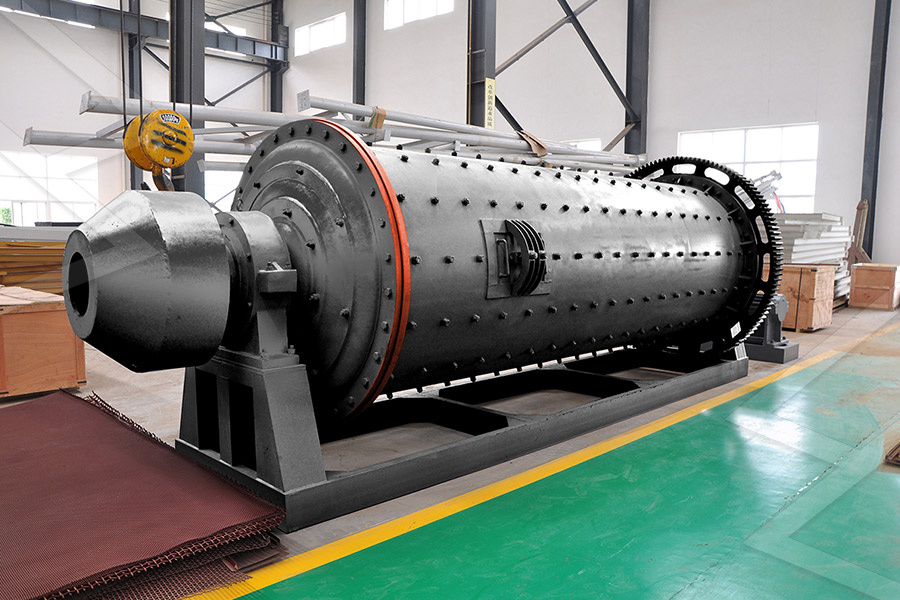

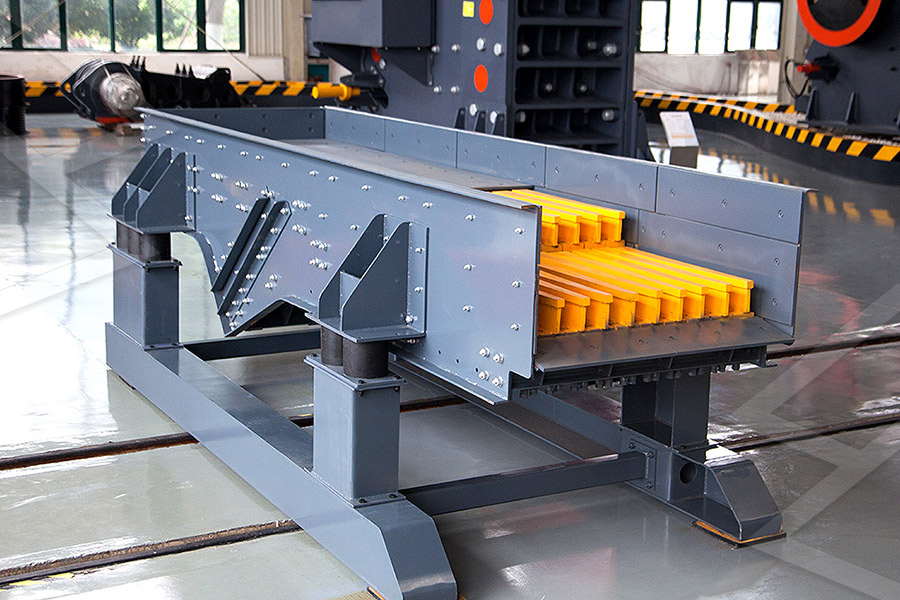

With over 5 decades of manufacturing experience in technical ceramics coupled with modern manufacturing facilities, we at Jyoti Ceramic offer CAD/CAM designed, custom engineered mill Ceramic ball mill liners, also known as the alumina ceramic lining brick, is a high alumina lining brick that can be used for grinding glaze and ceramic tile embryos The product has characteristics such as high hardness, low wear, good China Ceramic Ball Mill Liner Manufacturers Ceramic ball mill lining is widely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wearresisting material for material transfer equipment in mining, iron steel works, thermal powder plants, Ceramic Ball Mill LiningPaul O Abbe Equipment Company is a manufacturer New Ceramic Lined Ball Mills and Milling Equipment Call 8005242188 or request a quote to get startedCeramic Lined Ball Mills Paul O Abbe

%3C1PGHL[2}HK_]YT.jpg)

HighQuality Ball Mills for Efficient Grinding Pulva

We offer ball and pebble mill grinders with the option for ceramic interior lining to enable greater efficiency The ceramic lining comprises aluminum oxide brick, a hard material that increases Discover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining Ideal for ceramic, chemical, metallurgical, and building materials Stainless Steel Dry Powder/Liquid Horizontal Ball Mill Ceramic HJMT is one of the most professional ceramic ball mill manufacturers and suppliers in China Please feel free to buy high quality ceramic ball mill for sale here from our factory Good China Ceramic Ball Mill Suppliers, Manufacturers, Factory Ceramic 2024年8月8日 Ceramic balls offer high durability and minimal contamination, making them ideal for applications requiring high purity Steel balls, recognized for their robustness, are better suited for heavyduty milling tasks where material Ball Mill Success: A StepbyStep Guide to

Customised Vulco® Mill Lining Systems Weir Weir Group

Depending on your goals and application, we offer a range of premium composite and rubber mill lining solutions for rod, ball, AG and SAG mills Rubber mill lining is predominately used for Alsing type ball mills are used for wet grinding of solid materials, minerals, chemical products, ceramic glazes, pigments, etc in order to obtain, without pregrinding, homogeneous compounds free from external contaminationBall mills for sanitary ware production SetecThe total life of a high manganese steel lining plate is about 50006000 hours, and it is mostly used in medium and small ball mills Ceramic lining: ceramic lining plates have excellent wear resistance, corrosion resistance, and insulation Several Types Of Ball Mill Liners You Should KnowThe ball mill liner has the advantages of low energy consumption, high wear resistance, low noise, and easy installation Through the actual test, compared with manganese steel lining, the ball mill with rubber lining installed in a mine Mill Linings for Sale, Types of Ball Mill Liners

.jpg)

What is alumina lining brick and product application

Alumina lining brick is also called alumina ceramic lining brick, ball mill lining brick, ball mill lining board, wearresistant ceramic lining brick and so on It has the characteristics of high hardness, high density, low abrasion, good regularity, corrosion resistance, etc It is mainly used for the wearresistant lining ofAlumina wearresistant ceramic lining bricks can increase the service life of ball mill linings We analyze from the following perspectives: Working principle of ball mill: As an important equipment for refining solid materials, ball mills are widely used in construction, cement, metallurgy, chemical, ceramics, electric power, medicine, and defense industriesApplication of alumina wearresistant lining brick in ball millAlumina lining brick is also called alumina ceramic lining brick, ball mill lining brick, ball mill lining board, wearresistant ceramic lining brick and so on It has the characteristics of high hardness, high density, low abrasion, good regularity, corrosion resistance, etc It is mainly used for the wearresistant lining of ball mills, and Effective assistant for ball mill lining with wear resistance and We offer ball and pebble mill grinders with the option for ceramic interior lining to enable greater efficiency The ceramic lining comprises aluminum oxide brick, a hard material that increases the system's grinding strength With a Mohs scale rating of nine, the ceramic lining is hard enough to withstand collisions with any industrial materialHighQuality Ball Mills for Efficient Grinding Pulva

.jpg)

Steatite Ceramic Grinding Balls and Media Steatite ceramic

Steatite ceramic balls and mill lining bricks are manufactured from the same finegrained composite and are ideal performance partner Thus, they retain their shape better and last longer than flint / river pebbles, natural stones, porcelain etc Due to their higher density, hardness, toughness and a higher degree of sphericity, Steatite ceramic grinding media saves over 20 The Tega DynaWear® rubber lining system is the preferred lining system for secondary ball mills, regrind mills and scrubbers DynaWear® rubber mill linings are individually designed for your particular working conditions and goals, with a variety of profiles and materials available for specific applicationsTega DynaWear Rubber Mill Liner Manufacturer and SupplierTrelleborg has been providing mill lining systems since 1920 The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption Full lining kits are designed and supplied including Lifter bars, shell plates, pulp lifters, fasteners and discharge gratesMill Lining Systems FluidHandling TrelleborgOur standard design Mills use tapered roller bearings mounted on machine turned trunnions, assuring long life and smooth operation Mill Stands are of fabricated steel allowing for the discharge clearance required by the customer Economy Ball Mills are powered by high start torque motors and, depending on customer preference and design requirements, a direct Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc

.jpg)

Ceramic Balls 92% High Alumina Ceramic

Manufacturer of Ceramic Balls 92% High Alumina Ceramic Grinding Media, Ball Mill Lining Bricks, Steatite Ceramic Grinding Media offered by Khushbu Industries, Ahmedabad, Gujarat Khushbu Industries Vatva, Ahmedabad, 2024年11月13日 Advantages and features of the ceramic ball mill The grinding fineness depends on the milling time The motor of the ceramic ball mill is started by the coupling reduce voltage which lowers the starting electricity and the ball Ceramic Ball Mill For Grinding Materials FTM 2016年1月5日 Mill HEAD LINERS Head liners are of the segmental type constructed of Manganese Steel, Chrome molybdenum, or NiHard and are designed to pass easily through the manhole opening or discharge opening in Ball Mill Liner Design 911MetallurgistWe can provide customers with comprehensive and overall solutions, which is not only reflected in the ceramic rolled ball, abrasion resistant alumina lining, Ceramic Lining Brick, Curved ceramic alumina tile design, but also includes the improvement of operational efficiency and aftersales service support We're known as one of the most professional alumina mill lining China alumina mill lining Manufacturers Factory Suppliers WINCERAMIC

.jpg)

The Role Of Wearresistant Ceramic Liner in Ball Mill

The ball mill ceramic wearresistant lining plate consists of three parts: the ball mill straight plate, the ceramic guard plate and the bolts This design is simple in structure, convenient in installation and convenient for later maintenance The straight plate of the ball mill is a rectangular blunt plate, and the ceramic guard plate is a 2024年8月8日 Ceramic balls offer high durability and minimal contamination, making them ideal for applications requiring high purity Steel balls, recognized for their robustness, are better suited for heavyduty milling tasks where material hardness is a significant factor Consider the pros and cons of each media type in the context of your specific needsBall Mill Success: A StepbyStep Guide to Choosing precise ceramicA ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition and at still higher speeds they are thrown greater distances and considerable wear of the lining of the mill takes place paints, ceramics etc The ball milling owns the strengths of simple raw materials Ball Mill an overview ScienceDirect TopicsProduct introduction: The highend wearresisting alumina ceramic lining board is our company's characteristic product, belongs to the highend customized product, the main customers are tangshan guohua, weihai shangpin and some domestic equipment import and export companies, 19 years sales volume of more than 10 millionBall Mill Lining wearceramic

Wear Resistant Ceramic Lining

We're professional wear resistant ceramic lining manufacturers and suppliers in China, specialized in providing high quality ceramic materials Wear resistant ceramic lining is mainly used in hoppers,pipes,elbows,fan blades,chutes,ball mills etc in steel,thermal power,cement,coal,mine,chemical industry etc Specification Available: Size Ceramic ball mill is a ball mill whose lining plate is made of ceramic Ball mill is the key equipment used in grinding of materials after being primarily crushed, which is widely used in the manufacturing industry of cement, silicate product, new building material, refractory, fertilizer, mineral processing of black and nonferrous metals as Ceramic Ball MillHenan Hongke Heavy Machinery Co, LtdWe have a wide range of inhouse built and imported ball mills Both batch and continuous feed mills are available with steel, rubber or ceramic replaceable lining Both batch and continuous feed mills are available with steel, rubber or ceramic replaceable lining Custom builds are available, contact us for more information Sort by Batch Ball Mills Armstrong IndustriesAlumina lining brick is also called alumina ceramic lining brick, ball mill lining brick, ball mill lining board, wearresistant ceramic lining brick and so on It has the characteristics of high hardness, high density, low abrasion, good regularity, corrosion resistance, etc It is mainly used for the wearresistant lining of ball mills, and Effective assistant for ball mill lining with wear resistance and

Ball Mill Application and Design Paul O Abbe

These materials include AR 400, highchrome abrasion resistant steel, natural rubber lining, polyurethane lining, and high alumina ceramic brick (ie, aluminum oxide) lined mills Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they are as little as 12” in length 2024年9月30日 With the widest range of ceramic grinding medias available to the mineral processing market,Chemshun is able to supply your complete needs for mineral processing ultra fine grinding, applications including low purity alumina, high purity alumina and zirconia toughened alumina for tower mills, ball mills, stirred millsAlumina Ceramic Grinding Balls for MiningThe wear resistance of ceramic ball mill lining is 266 times that of manganese steel, with a long service life 3 High acid and alkali resistance 4 High corrosion resistance, high density, high mechanical strength Product specific information Product pictures Parameter sheets Properties Unit Value AL 2 O 3 % ≥92 ≥95 Fe 2 O 3 % China Ceramic Ball Mill Liner Manufacturers Suppliers Depending on your goals and application, we offer a range of premium composite and rubber mill lining solutions for rod, ball, AG and SAG mills Rubber mill lining is predominately used for smaller secondary and tertiary ball milling (regrind), whereas our composite mill liners (made from one or more materials) are used for heavyduty primary and secondary AG / SAG mill lining Customised Vulco® Mill Lining Systems Weir Weir Group

.jpg)

Ceramic lining bricks for ball mill lining LinkedIn

2023年4月19日 The ceramic lining brick of the ball mill, also known as the alumina ceramic lining brick, is a high alumina lining brick that can be used for grinding glaze and ceramic tile embryos The product Ball Mill with Cooling Water and Ceramic Lining (64CBM), Big Import Ball Mill with Cooling Water and Ceramic Lining (64CBM) directly from China factory, Wuxi Huihao stone stone Machinery Co, Ltd, and enjoy FREE trade Ball Mill Ceramic Lining Crusher MillsThe company covers an area of 20, 000 square meters, has four specialized production lines, 16 large ball mills, more than 20 isostatic presses, and has an advanced laboratory with a full set of highend experimental instruments, testing equipment and highquality scientific researchers High Quality and High Hardness Weldable Wear Ceramic Ball Manufacturer, WearResistant Materials, Ceramic The total life of a high manganese steel lining plate is about 50006000 hours, and it is mostly used in medium and small ball mills Ceramic lining: ceramic lining plates have excellent wear resistance, corrosion resistance, and insulation Several Types Of Ball Mill Liners You Should Know

.jpg)

Mill Linings for Sale, Types of Ball Mill Liners

The ball mill liner has the advantages of low energy consumption, high wear resistance, low noise, and easy installation Through the actual test, compared with manganese steel lining, the ball mill with rubber lining installed in a mine Alumina lining brick is also called alumina ceramic lining brick, ball mill lining brick, ball mill lining board, wearresistant ceramic lining brick and so on It has the characteristics of high hardness, high density, low abrasion, good regularity, corrosion resistance, etc It is mainly used for the wearresistant lining ofWhat is alumina lining brick and product application Alumina wearresistant ceramic lining bricks can increase the service life of ball mill linings We analyze from the following perspectives: Working principle of ball mill: As an important equipment for refining solid materials, ball mills are widely used in construction, cement, metallurgy, chemical, ceramics, electric power, medicine, and defense industriesApplication of alumina wearresistant lining brick in ball millAlumina lining brick is also called alumina ceramic lining brick, ball mill lining brick, ball mill lining board, wearresistant ceramic lining brick and so on It has the characteristics of high hardness, high density, low abrasion, good regularity, corrosion resistance, etc It is mainly used for the wearresistant lining of ball mills, and Effective assistant for ball mill lining with wear resistance and

.jpg)

HighQuality Ball Mills for Efficient Grinding Pulva

We offer ball and pebble mill grinders with the option for ceramic interior lining to enable greater efficiency The ceramic lining comprises aluminum oxide brick, a hard material that increases the system's grinding strength With a Mohs scale rating of nine, the ceramic lining is hard enough to withstand collisions with any industrial materialSteatite ceramic balls and mill lining bricks are manufactured from the same finegrained composite and are ideal performance partner Thus, they retain their shape better and last longer than flint / river pebbles, natural stones, porcelain etc Due to their higher density, hardness, toughness and a higher degree of sphericity, Steatite ceramic grinding media saves over 20 Steatite Ceramic Grinding Balls and Media Steatite ceramic The Tega DynaWear® rubber lining system is the preferred lining system for secondary ball mills, regrind mills and scrubbers DynaWear® rubber mill linings are individually designed for your particular working conditions and goals, with a variety of profiles and materials available for specific applicationsTega DynaWear Rubber Mill Liner Manufacturer and SupplierTrelleborg has been providing mill lining systems since 1920 The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption Full lining kits are designed and supplied including Lifter bars, shell plates, pulp lifters, fasteners and discharge gratesMill Lining Systems FluidHandling Trelleborg

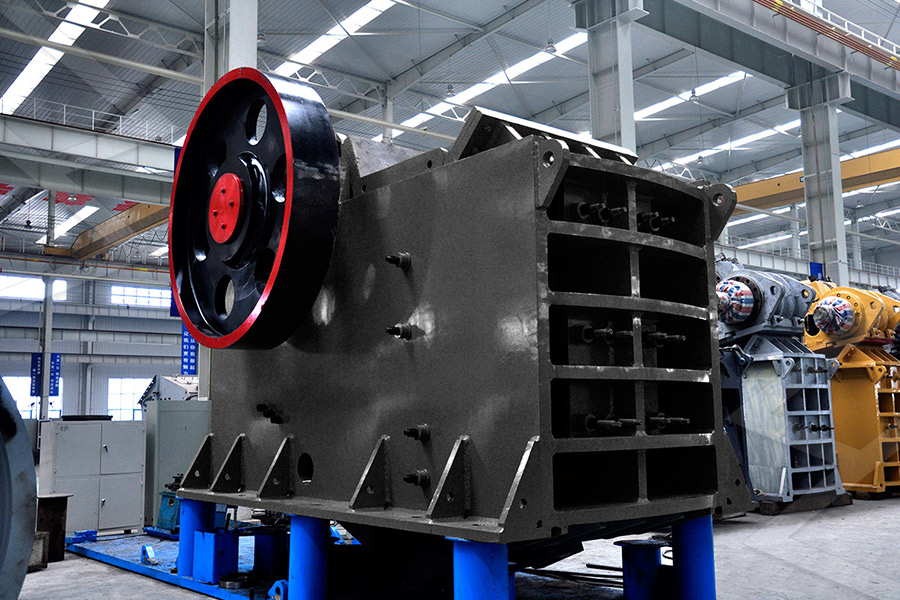

Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc

Our standard design Mills use tapered roller bearings mounted on machine turned trunnions, assuring long life and smooth operation Mill Stands are of fabricated steel allowing for the discharge clearance required by the customer Economy Ball Mills are powered by high start torque motors and, depending on customer preference and design requirements, a direct