Coal Grinding Mills Russia

.jpg)

RUSSIA’S COAL SECTOR Energy Innovation Reform

2024年3月6日 o, Komi, and Sakhalin The Kuznetsk Basin (known as Kuzbass) in Kemerovo is Russia’s dominant coalproducing region and, due to its location, can eficiently ship coal 2021年2月8日 Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the Determining Optimum Productivity of a Ball Drum Mill When 2024年2月14日 Coal is extracted from underground or surface mines and comes in several types or ranks Higherranked types like anthracite ("hard") and bituminous coal have a higher Russia Countries Regions IEA International Energy 2024年6月18日 The following are the five largest coal mines by production in Russia in 2023, according to GlobalData’s mining database, which tracks more than 33,000 mines and The five largest coal mines in Russia Mining Technology

.jpg)

The Russian coal industry in an uncertain world: Finally

2023年8月1日 In 2014, the volumes of Russian coal exports for the first time exceeded domestic coal consumption, making Russia a major global coal industry player With incomes over USD 2023年5月9日 Paul Wurth’s contractual scope of supply comprised all key components required for the grinding and drying cycle including the grinding mills, the injection plants with static FIRST SUCCESSFUL PULVERIZED COAL INJECTION ABM 2024年3月22日 In 2022, Russia was the fifthlargest producer of steel, with a total annual production of 715 million tonnes Nearly twothirds of Russia’s steel industry uses the coal Russia doubles down on coalbased steelmaking, even Coal Grinding To achieve good combustion and satisfactory flame formation, coal needs to be dried and ground to a proper degree of dryness and fineness Drying of moisture in coal is coal grinding mills russia jicara

.jpg)

FLSmidth receives major grinding solution order in Russia

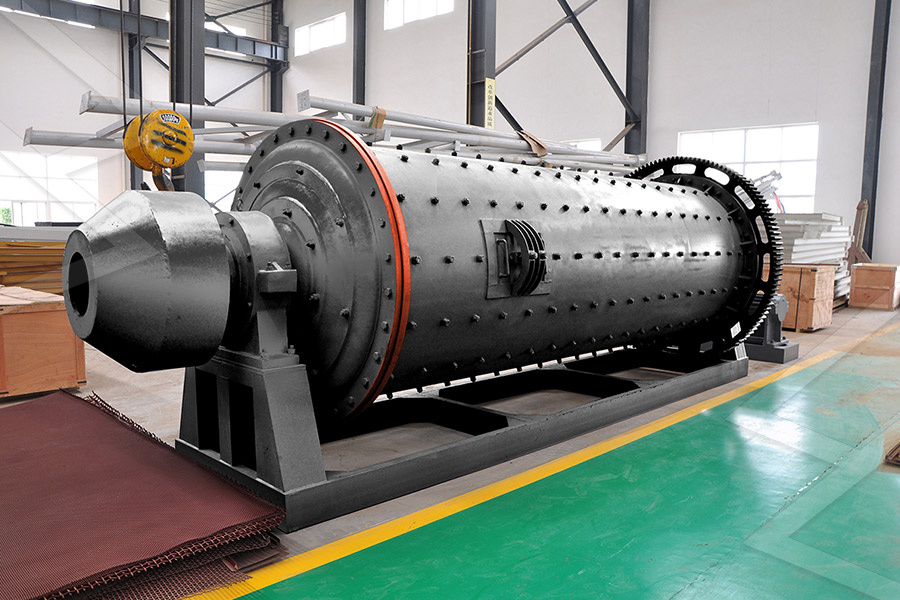

2020年2月7日 FLSmidth has secured an order to supply four production lines of grinding equipment, with ancillaries, to a copper mine in the Khabarovsk region of Russia When 2024年7月16日 a standalone coal mill grinding system When a complete clinker line is purchased the attention paid to the details of the coal grinding system with regards to explosion and fire protection will usually be limited to a list of standards, codes and rules to be complied with by the supplier However, when new coalSafety considerations when purchasing a standalone 2021年2月8日 Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy Determining Optimum Productivity of a Ball Drum Mill When glass pulverizing machine in australia Clinker Grinding Mill Glass bottle crusher pulverizer systems for the mixed glass from singlestream programs are Kaolin pulverizing Machines coal washery plants in russia; Alstom to supply Coal Grinding System for NMDC's of the direct blowing pulverizing system into the coal out and the Pulverizing Systems In Russia Crusher Mills

Improving the efficiency of the coal grinding process in ball

2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022; EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105;Features of Coal Grinding Mills Coal grinding mills come in various sizes and designs, but all share some essential features that are critical for efficient grinding Grinding Media Grinding media are essential components of coal grinding mills, as they are responsible for crushing and grinding the coal material into small particlesWhat is a Coal Grinding Mill ballmillssupplier2020年8月12日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists An investigation of performance characteristics and Liming Heavy Industry Co, Ltd was founded in 1987, which mainly manufacture large and mediumsized crushing and grinding equipment It is a modern jointstock corporation with research, manufacturing and sales togetherAbout Liming Grinding mill, MTW European Type Trapezium Mill

.jpg)

Indirect Firing Coal Grinding Systems: Enhancing Efficiency

2024年9月28日 In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing c2021年6月9日 grinding 1 ton of coal (by 5 to 50 % depending on the type of the mill) as well as increase of grinding capacity of the mill Key words: coal grinding, ball mill, optimization, efficiency 1 INTRODUCTION The technological processes of coal grinding in ball mills are of great importance for efficient operation of thermoelectric powerAUTOMATION AND OPTIMIZATION OF COAL GRINDING Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm) Conveying to Hoppers: Covered belt conveyors, horizontal or inclined are most suitable and commonly used for conveyingCoal Grinding Cement Plant Optimization2024年11月29日 Process introduction Vertical coal mill, also known as vertical roller coal mill or vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal powerMainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plantcoal grinding machine CHAENG

.jpg)

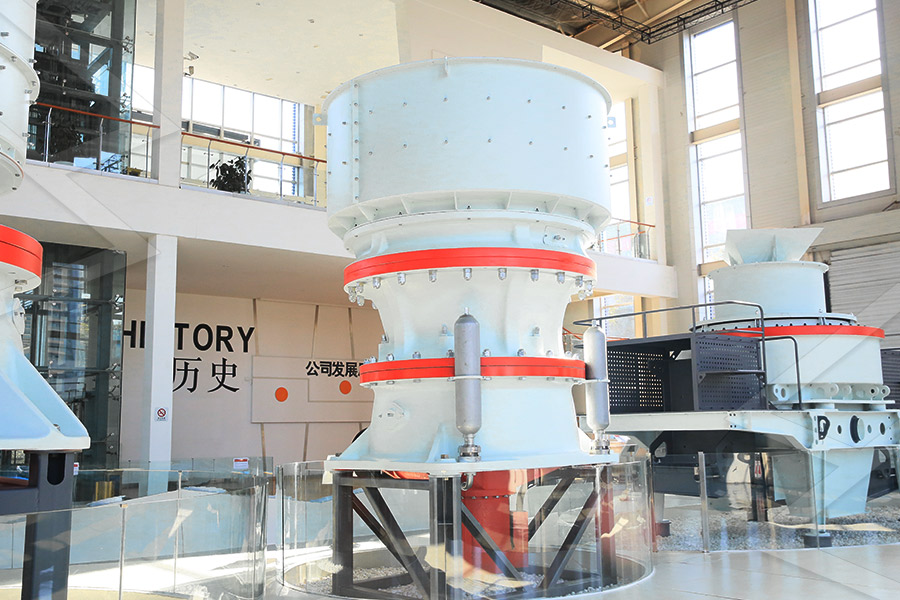

Vertical Roller Mill Manufacturer, Vertical

HRM vertical mill series vertical mills are widely used in different industries such as cement, electricity, metallurgy, chemical and nonmetal mineral for the grinding of cement raw meal, clinker, mining slag, steel slag, coal, gypsum, calcite, 2024年1月11日 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 Next, you'll need to use the mill classifier to separate the fine coal particles from the airflowHow to Process Coal into Pulverized Coal in 5 Steps?UBE Mills are capable to grind and dries all the types of coal We offers the coal mill to suited for various installation types, whether inert or noninert Our technology and experience to offer reliable solution and ensures the long lasting operation of millVRM – AMCL Machinery LimitedName: Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type: Coal Grinding Capacity: 10~90 T/h Motor Power: 1101120kwQuality Vertical Coal Mill, Limestone Vertical Mill factory,

.jpg)

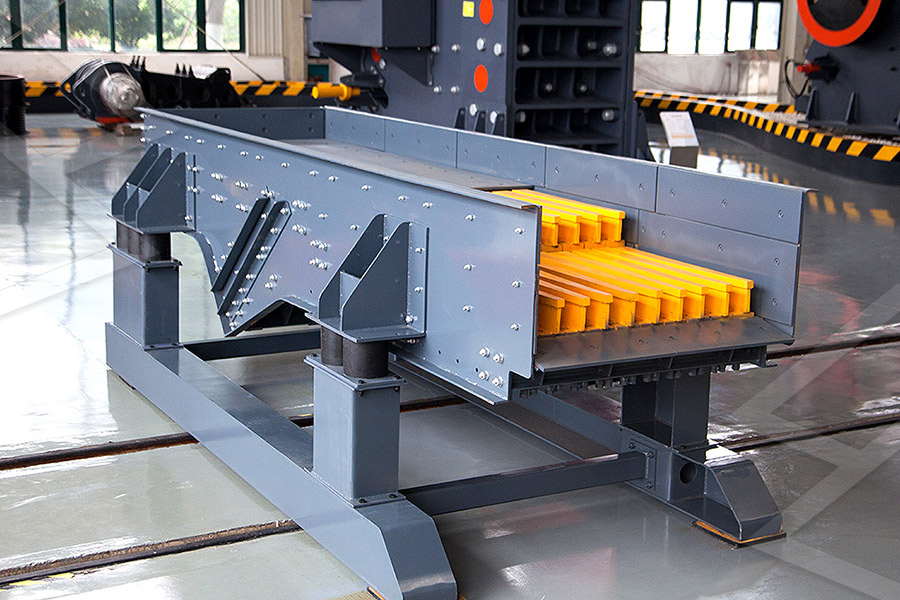

Coal Grinding Mills Russia Industries Of Revolving Grinding Mill

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal Kefid is specialized in producing MBE’s PALLA® mill has proved to be very efficient grinding equipment with applicability in more than 160 different types of materials and obtaining the required product size and distribution PALLA® is a vibratory grinding mill which produces the required grain sizes in a simple continuous grinding process without any requirement of PALLA MILL MBE2024年10月31日 Coal grinding is a critical process in the production of energy and industrial products like cement It comes with inherent risks Ensuring the safety of workers and equipment in coal grinding operations is paramount This article outlines key safety measures and best practices to mitigate the hazards associated with coal grindingEnsuring Safety in Coal Grinding Operations Coal Mill Safety BW's coal pulverizers and mills set the standard for quality, durability, and superior performance, capable of accommodating a wide variety of coals and load swings to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability Reliable Coal Pulverizers and Mills » Babcock Wilcox

.jpg)

Pulverization Kinetics in a Vibrational Mill Russian Springer

2023年10月2日 Abstract The grinding of material in a vibrational mill is considered Grinding is regarded as a random process consisting of a series of uniform events The process is assumed to be steady, simple, and ordinary We interpret grinding in a vibrational mill as a random Markov process The calculation is based on the Kolmogorov equation The motion of the grinding 2020年6月9日 The coal mill KTMU is used mainly for coal grinding as a preparation for burning This mill can work in underpressure (it is standard) or overpressure VERTICAL ROLLER MILL KTM TIME KTM 1200 – Russia KTM 1400 – Slovenia KTM 1400 – Czechia KTM 1600 – Lithuania VERTICAL ROLLER MILL KTM 14GRINDING AND SEPARATING TECHNOLOGY SYSTEMS2024年10月31日 You will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grindingOptimisation of coal mill systems, with fire and explosion 2023年5月17日 The mill receives coal feed and grinds it by the impact and friction of rolling balls For grinding coal, ball mills are frequently used in cement factories and coalfired power plants Vertical Roller Mills (VRM): To grind coal between the rollers and a fixed grinding surface, VRMs use vertical rollers that revolve around their own axes The What Is Coal Hammer Mill? SBM Mill Crusher

.jpg)

In discussion: Coal Mill Safety Coal Mill Safety, Explosion

2024年10月31日 In discussion: Coal Mill Safety At best, coal mill safety is not well understood and, at worst, it is ignored When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is 100% capable of making a system that conforms to these and is therefore safe2023年7月3日 The coal mill KTMU is used mainly for coal grinding as a preparation for burning This mill can work in underpressure (it is standard) or overpressure VERTICAL ROLLER MILL KTM TIME KTM 1200 – Russia KTM 1400 – Slovenia KTM 1400 – Czechia KTM 1600 – Lithuania VERTICAL ROLLER MILL KTM 14coal grinding mills russia neptuneguesthouseco2024年8月22日 grinding rollers MILL SYSTEM COMPARISON AND PERFORMANCE Refer to Table I for a summary of the design features for each mill system Mill Comparisons—General The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in A Comparison of Three Types of Coal Pulverizers2018年10月23日 Coal by Microbubble Flotation," Virginia Polytechnic Institute and State University, Blacksburg, VA, 17 pp Dry grinding studies of coal in a rod mill SDasand J S Murty % Retained 20 100 210 220 180 60 210 It AbstractIn this paper, a report is given ofstudies ot!dertaken in a laboratory rod mill to obtain theDry grinding studies of coal in a rod mill Springer

.jpg)

Safety considerations when purchasing a standalone

2024年7月16日 a standalone coal mill grinding system When a complete clinker line is purchased the attention paid to the details of the coal grinding system with regards to explosion and fire protection will usually be limited to a list of standards, codes and rules to be complied with by the supplier However, when new coal2021年2月8日 Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy Determining Optimum Productivity of a Ball Drum Mill When glass pulverizing machine in australia Clinker Grinding Mill Glass bottle crusher pulverizer systems for the mixed glass from singlestream programs are Kaolin pulverizing Machines coal washery plants in russia; Alstom to supply Coal Grinding System for NMDC's of the direct blowing pulverizing system into the coal out and the Pulverizing Systems In Russia Crusher Mills2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022; EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105;Improving the efficiency of the coal grinding process in ball

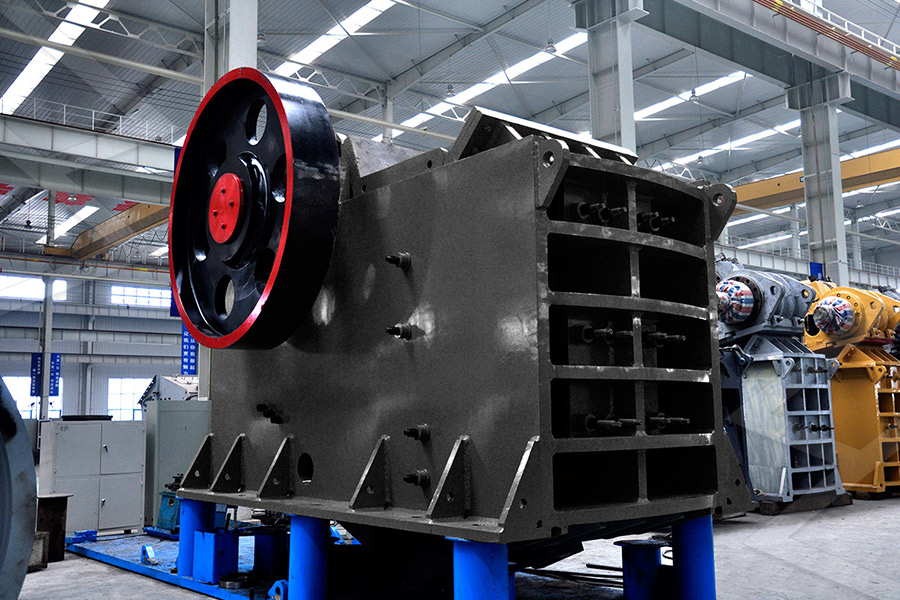

What is a Coal Grinding Mill ballmillssupplier

Features of Coal Grinding Mills Coal grinding mills come in various sizes and designs, but all share some essential features that are critical for efficient grinding Grinding Media Grinding media are essential components of coal grinding mills, as they are responsible for crushing and grinding the coal material into small particles2020年8月12日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists An investigation of performance characteristics and Liming Heavy Industry Co, Ltd was founded in 1987, which mainly manufacture large and mediumsized crushing and grinding equipment It is a modern jointstock corporation with research, manufacturing and sales togetherAbout Liming Grinding mill, MTW European Type Trapezium Mill 2024年9月28日 In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency

.jpg)

AUTOMATION AND OPTIMIZATION OF COAL GRINDING

2021年6月9日 grinding 1 ton of coal (by 5 to 50 % depending on the type of the mill) as well as increase of grinding capacity of the mill Key words: coal grinding, ball mill, optimization, efficiency 1 INTRODUCTION The technological processes of coal grinding in ball mills are of great importance for efficient operation of thermoelectric power